You’re sitting at your desk, life is great.

Something drops right into your hot mug of coffee.

The ceiling tiles fall onto your desk and behind you.

Your roof protects your building and the interior from the exterior elements and weather conditions. It’s one of the most critical parts of your building – keep it safe.

So what happens, why do commercial flat roofing solutions fail and leak?

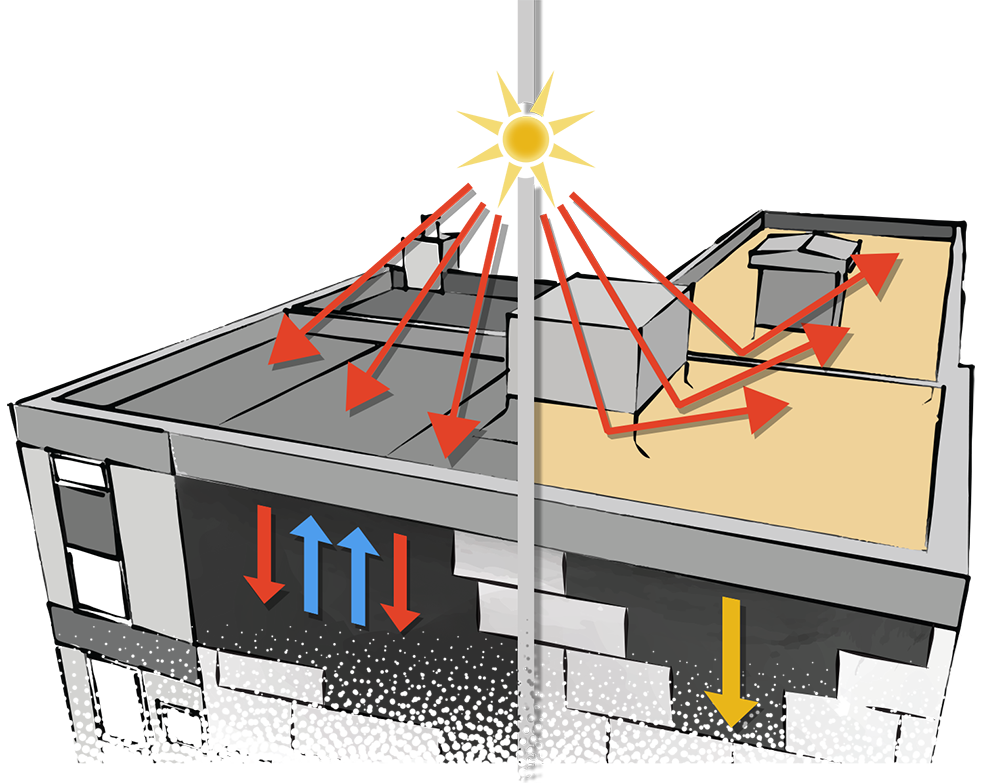

Diag. 1 – The sun hits your dark-colored roof, and causes the roof the heat up. In the summer months, the cool air inside is reacting with the hot air entering through the seams and cracks, this causes moisture to build up. That moisture can eat through your roofing sub straight, and your ceiling.

Your Roof is exposed to very harsh elemental conditions. Heat, cold, water, snow, the sun, hail, and a myriad of other weather conditions. The number one reason roofs fail is the roofing material, followed by age. Other factors like weather conditions, and roof color, also have a large impact on the condition and longevity of your flat roof.

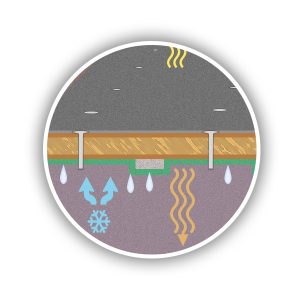

Some roofing is placed on in sheets, and then mechanically fastened (staples, nails). Those mechanically fastened sheets now are attached to the roof with a hole. Wood and metal will contract and expand depending on the weather conditions. Over time the holes punched into your roofing sub-straight (base/surface) will widen (because they expand and contract with the weather).

This also happens at the seams. These small holes and seams that are getting bigger year after year are made worse by penetrating water and escaping air, it’s a compounding issue.

Water can destroy anything. It will make metal rust and corrode, and cause wood to warp, and decompose. If that water gets into your sub straight, it will slowly, but surely, eat away at your roofing surface, until it doesn’t. Which means, the water is on the floor now, not the roof.

Air is a significant expander and contributes to the expansion and contraction of your sub straight at those seams. It’s also the number 1 reason why your energy bills are so high – Have a read here on energy consumption and roof types.

Roof types that have seams and are mechanically fastened include some EPDM, PVC Membrane, TPO, Modified Bitumen, and Built-Up Roofing.

Roof types that have no seams are spray-on and include Spray Foam and Silicone. These are seamless, and airtight and offer the best protection.

How spray foam is the best option for a new and restorative commercial flat roof.

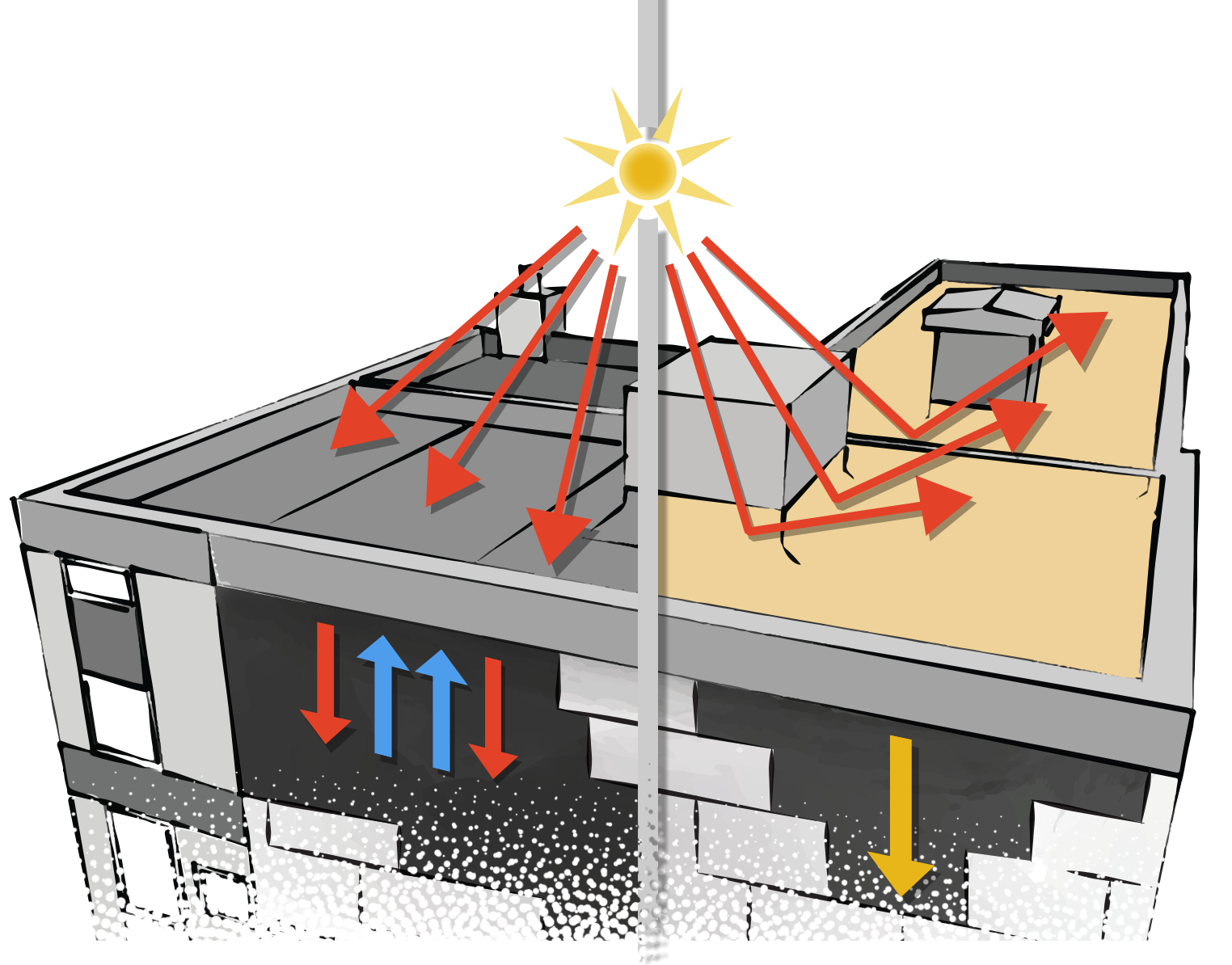

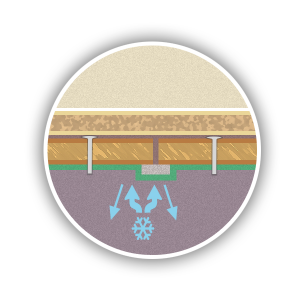

The spray foam coats the entire roof, seamlessly, and can cover your current roof. And your conditioned air inside stays conditioned.

1. It’s Seamless & Nail-Free.

Yes, it’s seamless meaning there are seams to open and get wider. This prevents the entry of water under the material. As we mentioned before, most common commercial flat roofing types have seams, and a hole is punched into the roof to attach it. Being that spray foam is seamless, spray-applied, and will never need to be nailed down – it means there is 0 chance of elemental exposure to your roofing sub straight. The spray application also means that the flashing (think baseboard for your roof) is applied with the roofing surface. It’s one continual coating.

2. It’s air-tight.

Yes, it’s air-tight. Meaning that the air that contributes to larger holes, cracks, and seams is eliminated. Air can’t escape (except where engineered), and air can’t penetrate. This stops air from contributing to high energy bills, and widening gaps, and holes in your roof.

3. It’s an insulator.

Spray foam is a dense, pollution-free, polyurethane insulator. It has an R-Factor (measurement of insulation strength) that is greater than any other insulator. So you know what that means? Exactly, the heat and cold from inside and outside will not expand and contract your roofing sub straight. When it hardens, it also adds strength to your commercial flat roof and is nearly weightless.

4. It can be applied over your failing roof.

This is the best part. Spray-Foam can be fluid applied over your existing roof, regardless of the material. It will immediately stop penetrating water and those pesky weather conditions, and insulate and protect your building for a lifetime.

Spray foam is one of the best commercial flat roofing solutions available because it’s seamless, fluid applied, an insulator, it’s airtight and it can be applied over your current failing roof. Comparison Open vs. Closed Cell Foam

Spray foam commercial flat roofing solutions offer the best protection and for the longest time. There is a caveat – finding the right contractor to install it. It needs to be applied evenly, and consistently across the entire roof – always find a professional to install your spray foam.