A Guide to Spray Foam & Foamed-in-Place Insulation Types

What is spray foam insulation?

Spray foam insulation comes in many types. There is cementitious, a magnesium oxide cement-based foamed-in-place insulation material like shaving cream.Spray polyurethane foam (SPF Insulation), which is our (Stony Creek Services’s) expertise for more than 40 years. And there’s tripolymer, a water-soluble foam that is injected into cavities.

What spray foam insulation types exist?

There are two main types of spray foam insulation: open-cell foam and closed-cell foam. Open-cell foam has a lower density and is more permeable. This allows for better sound absorption but lower thermal resistance. Closed-cell foam has a higher density and is less permeable, providing better insulation and moisture resistance. Each type has its own advantages and is used in different applications based on specific needs.

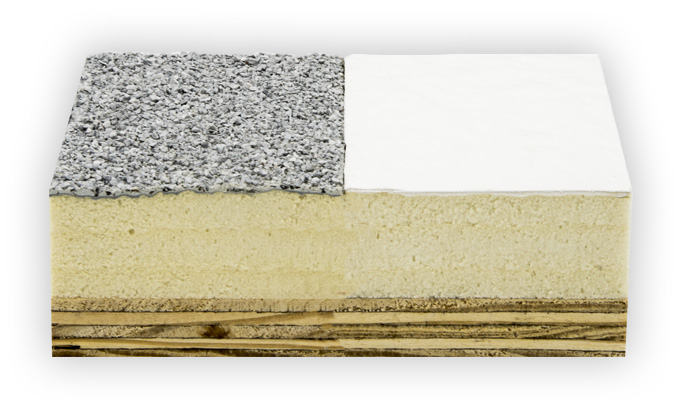

Spray Foam Flat Roofing. Dense pollution free – the diagram shows the profile of Spray Foam once applied to the sub straight.

Spray foams are dense, pollution-free insulators with an airtight, lightweight, and seamless application. Some types, like SPF, may also be waterproof. Spray foam is fluid-applied in place. It’s typically with either a small handheld sprayer or a pressurized sprayer, depending on the size of the project. It then expands and hardens on contact with the surface. Then cures to form an airtight chemical bond. Everything sprayed or fluid-applied is a better insulator naturally.

Cementitious Pros:

- Fire resistance: Cementitious spray foam insulation is non-combustible and provides excellent fire resistance, making it a safer option compared to other insulation materials.

- Eco-friendly: This type of insulation is made from natural and recycled materials, making it an environmentally friendly choice.

- Soundproofing: Cementitious spray foam insulation offers excellent sound absorption properties, effectively reducing noise transmission between rooms or from outside sources.

- Moisture resistance: The cement-based composition of this insulation makes it resistant to moisture, helping to prevent mold and mildew growth in damp environments.

- Pest resistance: Unlike some other insulation materials, cementitious spray foam insulation does not provide a food source for rodents or insects, reducing the risk

Spray Polyurethane Foam Pros:

- High R-value: SPF insulation offers a high R-value per inch, meaning it provides excellent thermal resistance and can help reduce energy consumption.

- Air sealing: SPF insulation expands upon application, filling gaps and cracks efficiently. This creates an effective air barrier, reducing drafts and improving indoor comfort.

- Moisture resistance: Closed-cell SPF insulation is resistant to moisture intrusion, helping to prevent mold and mildew growth in damp environments.

- Structural strength: Closed-cell SPF insulation can add structural strength to walls and roofs, potentially increasing the overall stability of a building.

- Versatility: SPF insulation can be applied to various surfaces and in difficult-to-reach areas, making it suitable for a wide range of applications.

- Noise reduction: SPF insulation can help reduce noise transmission between rooms or from outside sources, contributing to a quieter indoor environment.

Benefits

Aside from strengthening your building, spray foam is low maintenance, stops other problems from arising, and reduces construction waste. Spray foam will not sink, sag, or settle, and does not wear down the structure. It is also safe for application over fireproofing materials. Over the last 35 years, it has undergone many tests to conform to the standards for non-combustibility, and it keeps passing.

With a spray foam insulation solution, the cold and heat from inside and outside will not expand and contract your roofing substrate and will keep the air-conditioned or heated air you pay for inside of your building. This also means that any wood in its surrounding vicinity will not rot, split, or warp. Oftentimes, certain spray foams are used in conjunction with a roof coating, such as our silicone roof coating solution, to form the primary protective roof covering.

Spray foam is incredibly strong with an R-Value greater than any other insulation type on the market. The R-Value is how insulation strength is measured. And how much heat the insulation will let flow through it. Depending on the thickness of your walls and the foam density, our closed-cell SPF’s R-Values here at Stony Creek Services are between R-6 and R-6.5 per inch. In comparison, fiberglass batts and blankets have an R-Value of 3.0 to 4.0 per inch. In general, closed-cell spray foam is the better insulation material for keeping the weather, water, air, and even bugs and mold out.

Uses

The list of commercial and industrial spray foam applications is long. It is quite versatile and has many different applications, from commercial and industrial buildings (interior and exterior walls) to refrigerated trucks and vans to water storage tanks and duct work. Spray foam can be applied to any commercial or industrial construction material, such as concrete block, concrete, brick, steel, wood, laminates, and even exterior sheathing boards.

It can be used for virtually any insulation need, including digesters, freezers and coolers, conveyor tubes, separation insulation between heated and unheated areas of your building, and even coatings for below-grade pipes, vaults, and manholes.

Spray foam is an excellent option for acoustical insulation projects as well with its impeccable sound-insulating properties. Not only that, but it is mold, pest, and pollutant-resistant, making it a smart insulation choice for your project whether it involves your home, commercial or industrial building, or refrigerated truck or van.

Energy & Cost-Saving Benefits

As cold or hot air enters a building, an equal amount is forced out, leading to air loss. Your HVAC system must work twice as hard to keep the temperature stable. Air loss is exactly how your hard-earned money is wasted. Spray foam insulation stops air loss and prevents leaks, production shutdowns, and equipment damage by creating a seamless barrier as well as filling any existing cracks, gaps, holes, and seams. In return, you get enormous cost savings just from keeping the air inside your building — right where it belongs.

Spray foam is proven to save up to 40% to 60% in annual energy costs. A 50,000 square foot industrial or office building will have energy costs around $67,000 per year. Once you have spray foam insulation installed, you can expect a savings of around $26,800 a year.

Even though spray foam insulation typically costs more than traditional insulation, the cost is mitigated by its benefits. Due to its high R-Values, it can virtually eliminate some of the other costs associated with constructing or maintaining a home or commercial building.

Spray Foam Insulation Densities

Spray foam insulation is available in low, medium, and high density types. At 0.5 pounds per cubic foot, low-density spray foam is an open-cell foam whereas medium and high-density spray foams at 2-3 pounds per cubic foot are both closed-cell foams. In general, the higher the density, the greater the R-Value; and the higher the R-Value, the greater the insulating power.

Open-Cell vs. Closed-Cell Spray Foam Insulation Types

Open-cell spray foam cures into a soft and sponge-like state because its cells are, as the name implies, open and filled with air. Closed-cell spray foam cures into a hard and rigid state because its cells are closed and filled with gas. Typically, closed-cell spray foam costs a bit more than open-cell foam. Closed-cell spray foam has a higher R-Value per inch due to its level of density. At 3” of application, open-cell spray foam becomes an effective air barrier. At only 1” of application, closed-cell spray foam becomes an excellent air barrier and is extremely useful for sealing air leaks as well as adding structural strength.

Open-Cell

- Low density: 0.5 lb. per cubic foot

- Up to R-4 per inch

- Soft & spongy – cells filled with air

- Water permeable (should be used in conjunction with a vapor retardant)

- Effective air barrier at 3” of application

- Attics, ceilings, roofs, soundproofing, walls

Closed-Cell

- Medium to high density: 2-3 lb. per cubic foot

- Up to R-7 per inch

- Hard & rigid – cells filled with gas

- Moisture-resistant, Class II vapor retarder, FEMA Class 5 flood-resistant

- Excellent air barrier at 1” of application

- Basements, ceilings, crawlspaces, roofs, slabs, sound-dampening, walls

Is Spray Foam Insulation Safe After it Cures?

The video outlines work we did in Shelby Township. Using a Silicone roof coating (one we put over spray foam after its applied), we’re able to prevent leaks, create energy efficiency with a lither color, and shore up the entire roofs structure.

In Closing

The type of spray foam that you need will ultimately depend on your project and budget. The installation of spray foam requires permits as well as personal protective equipment, so it is extremely important to contact a professional to take on the job.