Quick Fixes for Spray Foam Roof Systems

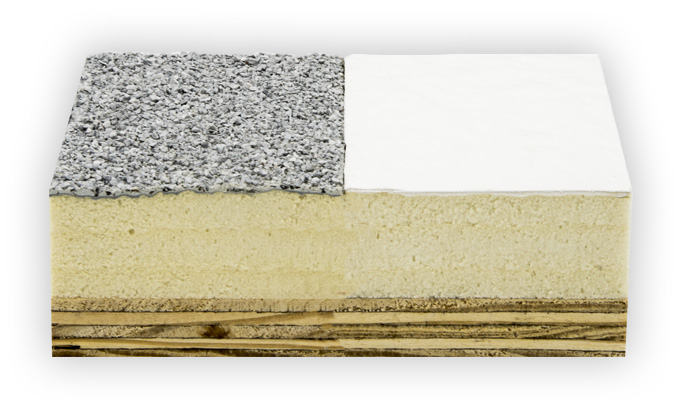

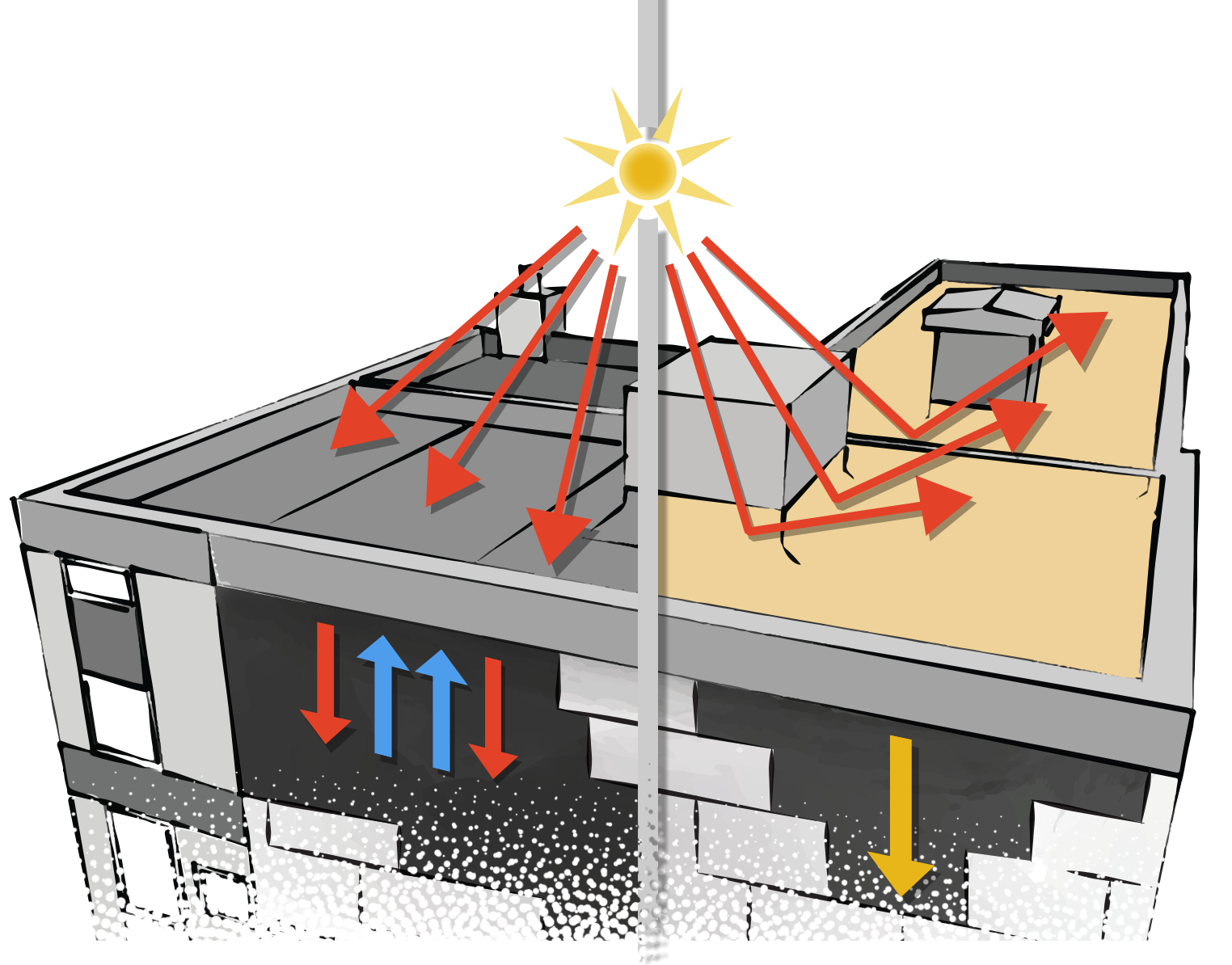

Maintaining a roof system is one of the most important ways to extend the lifespan of your property and keep it safe from weather elements. Spray foam roofs are an increasingly popular option for building owners. They offer versatile durability and efficient energy use, but like all structures, they benefit from regular inspections and maintenance. To help you keep up with care for your spray foam roof, here are some easy-to-implement quick fixes. These can ensure its proper functioning for years to come!

Inspect the roof regularly for any cracks, punctures, or damage

Maintaining a quality roof requires regular inspections. Inspections every season, every year, and after any major weather events. Find trusted professionals who can take a look and help you identify any existing damage. Or identify areas that may be susceptible to future problems. Need to determine if there’s any rot, punctures, open seams, cracks, or evidence of leaks (water staining) in tiles or shingles. Small damaged areas can cause big problems. Getting out regularly and identifying these issues early can lead to greater peace of mind and potential long-term savings on repairs.

Check for any gaps or open seams that need to be sealed

When it comes to sealing gaps and open seams, it’s important to check that all areas are sufficiently sealed. This is especially relevant in regions with severe weather conditions. As open seams can make your home susceptible to heat loss. Additionally, looking for any openings that need to be sealed can help keep out pests like rodents and insects. Taking a few minutes to check for any openings around the house can help maintain a comfortable temperature. It can also provide peace of mind when it comes to pest control.

Clean your spray foam roof system of debris, dirt, and leaves

Keeping your spray foam roof system free of debris, dirt, and leaves is essential for its longevity. Removing any buildup of materials can help to make sure that your roof system maintains its optimal condition and performance. Regularly cleaning your spray foam roof system will prevent damage from water or dirt build-up. It will also protect it from mold growth and deterioration. Taking a few minutes every few months or so to clean up the surface of your roof can ensure that you get the full use out of it for years to come.

Reapply sealant to exposed areas that may be damaged or worn down

Keeping your building or structure properly sealed is an important part of protecting it against water, humidity, and other outside elements. The sealant applied to your windows, doors, and other exposed areas is there to provide a barrier that is both effective and durable. However, over time these sealants can be worn down or damaged by external factors like heat, cold, and age. To ensure the security of your property, it’s essential that you reapply the sealant whenever you notice any damage or wear. So that further damage does not occur and your home remains protected. Regular reapplication of sealant will save you money and time in the long run. Reapplication helps protect against water damage, insulation issues, and more.

Replace any broken or missing parts of the roof system

Keeping a roof in good working condition is important for protecting a building’s occupants and contents from the elements. As such, it is important to be proactive and replace any broken or missing parts of the roof system as soon as possible. This may involve inspecting all components of the roof . Inspecting the fascia, rafters, soffits, and gutter systems to shingles, tiles or slates. And replacing parts that are no longer functioning correctly. With proper maintenance and repair, you can ensure your roof remains reliable for years to come.

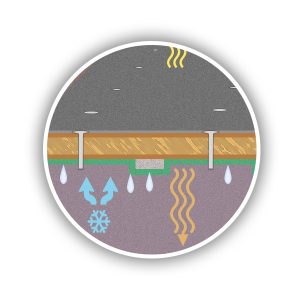

Monitor the temperature of your foam roof system – warm temperatures can cause it to expand and contract quickly, causing further damage

Maintaining your foam roof system by monitoring temperatures is of the utmost importance. Especially in warm weather. Where fast expansion and contraction due to extreme temperatures can cause serious damage. The best way to ensure that your foam roof remains in top condition is to keep an eye on the temperature readings. Making any necessary adjustments to avoid drastic changes. Regular inspections, either done yourself or by a roofing technician, can prevent a minor issue from becoming a major one. When it comes to foam roof systems, temperature control is key!

Preserving your roof system by getting into the habit of performing regular maintenance is key. Striving for a few minutes each month can have a huge impact on saving you time, money, and stress caused by potential damages in the future. It may seem tedious to inspect, clean, seal, and replace parts. But this will add years to the life of your foam roof system and save you from unexpected downtime and repairs. Don’t let yourself be caught off guard by an unexpected roof repair bill. Make sure to keep up-to-date on regularly scheduled inspections and maintenance!